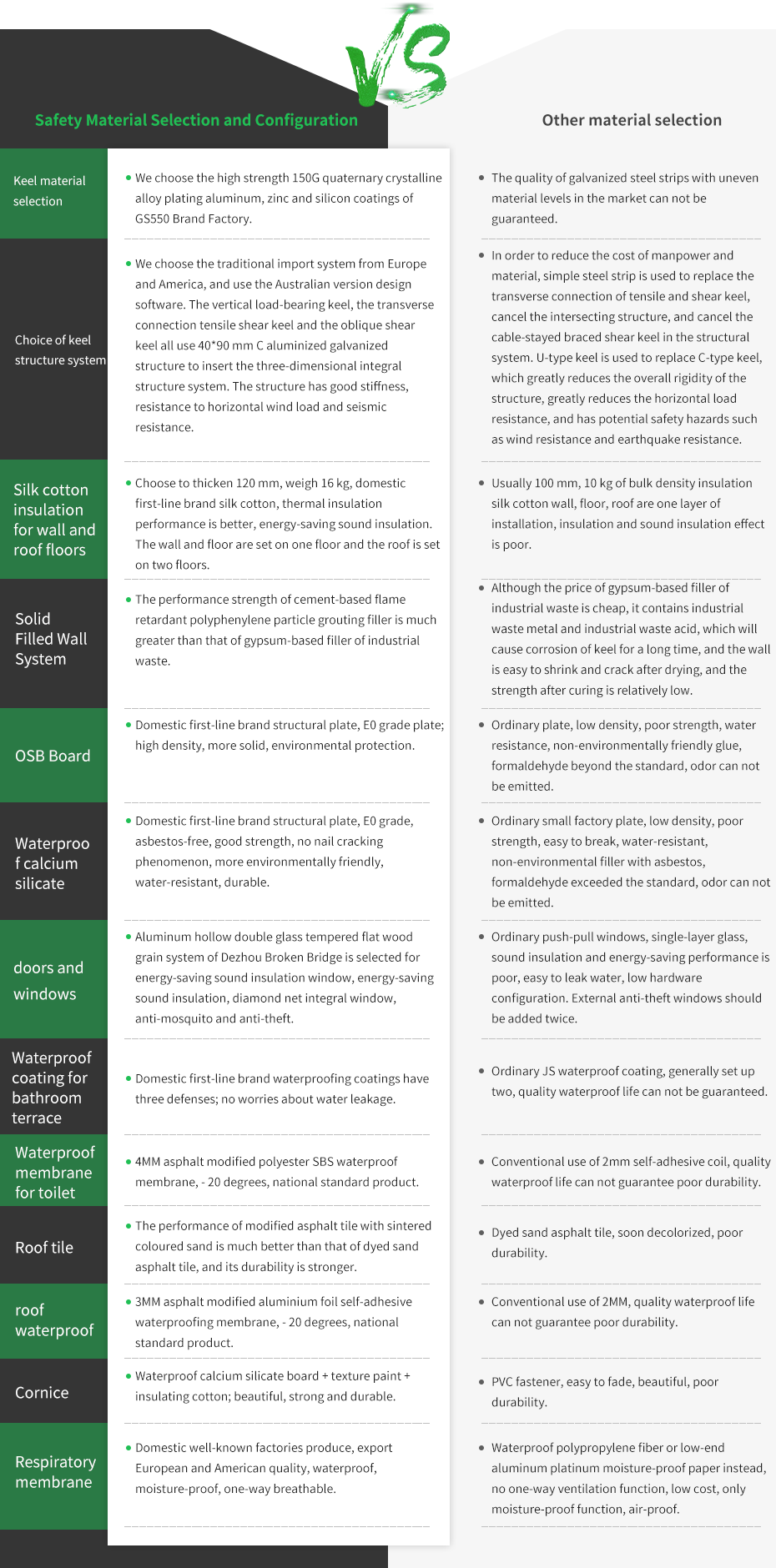

Contrast with peers

—— - Choice of security Selection quality - ——

In order to ensure that every house produced by Angu has excellent performance and high quality, we aim to focus on the high-end market with the business philosophy of focusing on, excellence and word of mouth. Ensure that sufficient efforts are made in material selection, process control and management of the construction team, and serve millions of households in the light of the development idea of not spreading out large amounts and only doing a good job.

|

Material selection: We only choose brand building materials suppliers, because we firmly believe that only good materials can make good houses.

|

|

|

Material configuration: Comparing with other similar businesses in the market;

|

|

|

|

|

Construction team selection management: In the field of Angu Deep-ploughing Construction for 18 years, we have not operated according to the rapid expansion mode, which is popular in the market, which results in uneven levels of construction teams, serious Jerry work and material reduction, unsafe construction quality and time limit, and confusion in management, etc. We will select the construction experience such as installation, decoration and meticulous and responsible workers to join the security team, after a certain period of professional training, after the completion of the training and evaluation of qualified certificates issued security training courses, security construction team qualifications, each project with the project manager signed a project responsibility letter; subregional companies have market managers to manage regional construction. Project manager, with each customer to establish a project manager, marketing manager communication platform, and regularly to participate in the project node acceptance, quality supervision and management of the whole process control; to facilitate customer complaints, timely problem solving. |

|

Component standards:

Pipeline control has become one of the important indicators of light steel production and processing. The keel adopted by Angu is manufactured on the Dingfeng X5 automatic production line of foreign specialty. Its own light steel production and processing system simplifies the responsibility without any other responsibility sharing. Strict assembly line increases the degree of workpiece, and is strictly controlled with small error and component standard.。

Self importance:

The self-weight of the light steel integrated building in Angu is light, the thickness of the enclosure wall is 14-20 cm, the cost of the foundation is low, the use area is increased by 10% compared with the traditional concrete building, and the construction period is short. (300 square meters of building, 6 workers can complete construction in 45 days).

House span length:

Most enterprises'light steel villas span only 6 meters, while Lida Group's light steel villas span up to 12 meters, this width greatly increases the use of light steel villas, office buildings, classrooms, activity rooms, business clubs and so on, will comprehensively address customer demand for light steel.

The indoor use rate is high:

Light steel housing has always been very high, the use rate of secure light steel villas can reach more than 92%. Take 200 flat houses for example, the extra 2% can get 200*2%=18 square meters of space, there will be an additional bedroom or storage room, the same price, the degree of space use, why not?

The construction period is short:

The construction period of Angu Light Steel Villa is shorter and can be completed in 5 weeks. Compared with other enterprises, the construction period is shortened by one month on the premise of quality and quantity.

Cold-formed thin-walled steel:

Angu all light steel products are cold-formed thin-walled steel. The structural components produced are composed of C-type, H-type and U-type cold-formed steel. The material thickness is 0.7-2 mm, the same industry is 0.55-1.5 mm, the yield strength is 345 MPa (G345), 550 MPa (G550), and the yield strength of light steel in the same industry is generally 90 MPa (G90). The amount of hot-dip galvanizing of Lida Group light steel is 275g and that of aluminium and zinc is 150g, which are all in the industry.